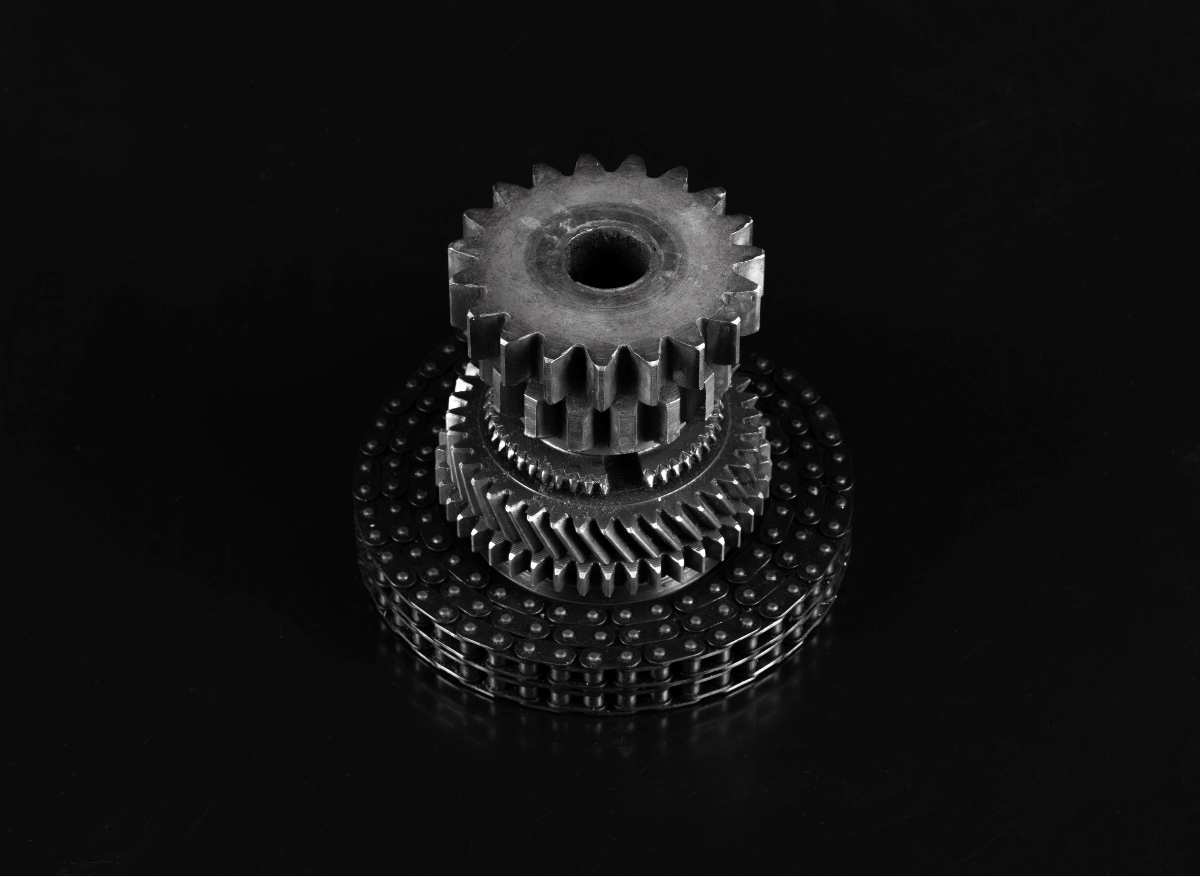

For businesses operating in remote or isolated locations, sourcing spare parts can present unique challenges. In this detailed analysis, we explore the strategies and solutions that companies can employ to overcome the obstacles associated with remote spare parts procurement.

One of the primary challenges of remote sourcing is limited access to suppliers and logistical infrastructure. We discuss innovative approaches to logistics, such as leveraging technology for real-time tracking and monitoring of shipments, as well as establishing strategic partnerships with local distributors to streamline the procurement process.

Additionally, we examine the importance of inventory management and strategic planning in remote spare parts procurement. By maintaining adequate stock levels and forecasting demand accurately, businesses can minimize the risk of stockouts and ensure the availability of critical parts when needed.

Furthermore, effective communication is essential for success in remote sourcing. We explore the use of digital communication tools and platforms to facilitate collaboration between stakeholders, as well as the importance of establishing clear lines of communication with suppliers to convey requirements and expectations effectively.

Moreover, we address the importance of building resilience and flexibility into the supply chain to mitigate the impact of unforeseen disruptions, such as adverse weather conditions or geopolitical instability. By diversifying sourcing options and developing contingency plans, businesses can minimize risks and ensure continuity of operations in remote environments.

In summary, navigating remote spare parts procurement requires a combination of strategic planning, effective communication, and adaptability. By implementing the strategies outlined in this article, businesses can overcome the challenges associated with remote sourcing and ensure the uninterrupted operation of their equipment, no matter where they are located.