In today’s interconnected world, businesses often rely on a global network of suppliers to source spare parts for their equipment. However, navigating the complexities of international sourcing can be daunting without the right strategies in place. In this comprehensive guide, we explore the key steps and considerations involved in mastering global spare parts sourcing.

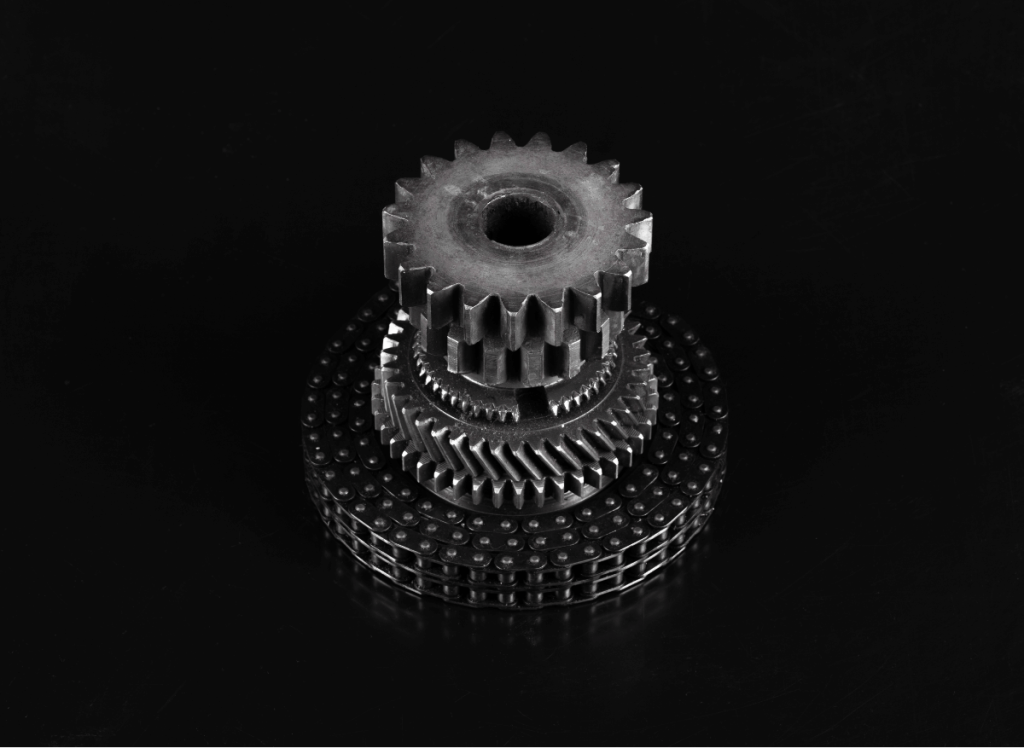

From the outset, it’s essential to prioritize quality assurance. Opting for genuine spare parts from reputable manufacturers ensures reliability and performance, minimizing the risk of equipment downtime and costly repairs down the line. We delve into the importance of conducting thorough due diligence when selecting suppliers, verifying certifications and quality control processes to guarantee the authenticity of the parts.

Logistics play a critical role in global spare parts sourcing, particularly when dealing with suppliers in different countries and time zones. We discuss best practices for managing the logistical challenges, from coordinating shipping and customs clearance to optimizing inventory management to minimize lead times.

Communication is another key factor in successful spare parts sourcing. Effective communication with suppliers is essential for clarifying requirements, negotiating terms, and resolving any issues that may arise during the procurement process. We provide practical tips for establishing clear lines of communication and maintaining productive relationships with suppliers to ensure smooth operations.

Furthermore, we address the importance of flexibility and adaptability in the face of unforeseen challenges, such as supply chain disruptions or changes in market conditions. By staying agile and proactive, businesses can mitigate risks and seize opportunities to optimize their spare parts sourcing strategy.

In summary, mastering global spare parts sourcing requires a combination of careful planning, attention to detail, and effective communication. By following the guidelines outlined in this guide, businesses can streamline their procurement process, reduce costs, and ensure the uninterrupted operation of their equipment, no matter where they are in the world.